Food processing is a significant driver of any local economy, creating supplier linkages for millions of small-scale farmers. Yet Food processing in Nigeria and other sub-Saharan African countries are virtually untapped. As population and urbanization rates rapidly increase across the region while hundreds of millions of people continue to face food insecurity, the demand for food has never been greater. Yet, small and growing local processors often have difficulties producing high-quality affordable and nutritious products that meet food safety standards and regulatory requirements due to a lack of technical, business knowledge and use of proper food processing equipment.

Food processing industry in Nigeria and other sub-Saharan African countries holds huge potential for growth. It is anticipated that by 2040, the value of food purchased in these regions of Africa will grow by seven folds.

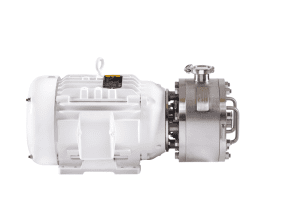

Many people are ready to make the leap into the future, however often handicapped with issues discussed above. On our part we specialize in American manufactured food processing equipment, specifically size reduction machines, and will touch on a few common questions that most people thinking of going into the food processing business often ask as far as equipment are concerned.

If you are starting a food processing business in Nigeria or other sub-Saharan African countries and Looking for size reduction equipment or Perhaps it’s time to replace your old, outdated machine? No matter what the case may be, Our American manufacturer has a variety of options available to you. That said, selecting the right equipment can be tough. Will it fit into your production space? How much maintenance will it require? How do you know you’re getting the right size? It can be a complicated process, to select the right equipment, but it doesn’t have to be.

In this write up, we will give you some information to help you learn more about size reduction equipment in the food processing industry, their applications, and how to choose the right fit for your company.

What is a food size reduction equipment?

Food Size reduction equipment is a family of food processing machines that specialize in reducing fibrous roots, fruits, cooked meats, dry cheeses, vegetables, legumes, nuts, and more. Sometimes disintegrators work best when combined with a Crusher, which works as a pre-chopper. In-Line mills, meanwhile, finish pump-able liquids like soup and baby food into a smooth, silky puree.

Who Uses These Machines?

Food Size reduction equipment has many applications but is prevalent primarily in food processing and pharmaceutical processing.

Regardless of industry, the primary purpose of size reduction equipment in the food industry is to add value to the food. The way food is processed determines what value is added, and this equals money. More juice from fewer apples, for example, makes good financial sense.

The Primary Types of Food Size Reduction Equipment

There are five primary types of size reduction machines in the food processing industry

Angle Disintegrators

Angle disintegrators are gravity-fed machines that sit at an angle. The reason they are angled is to facilitate better feeding to the grinding chamber. The tilt of the inlet allows the product to fall into the grinding chamber easier and more efficiently. Angle disintegrators are known for durability, flexibility and great for extractive food industries, including juice, oil and by products.

Angle disintegrators work well as an industrial food grinder. They’re also applicable to pharmaceutical processing duties. They are not, however, ideal for processing products that are prone to “bridging,” or getting stuck in the inlet, such as raw celery sticks or wet, leafy greens. These products are best processed by screw-fed disintegrators, instead.

One excellent example of a product that does work well in an angle disintegrator is apples. The average angle disintegrator made by our manufacturer can handle 45,000 pounds per hour of apples to ¼” pieces, for example. Despite their varied functionality, angle disintegrators are not applicable for slicing or dicing – only random cutting.

Screw-Fed Disintegrators

Screw-fed disintegrators process adhesive or other hard to feed products such as odd-shaped, oblong items, without “bridging.” They do this thanks to the moving screw in the feed chamber, which feeds everything into the grinding chamber without interruption. Screw-fed disintegrators best for materials that are sticky or otherwise difficult for gravity to move through processing machines. Examples would be leafy green veggies and also great for things like clumps of ginger, squash and oversized products. This machine is common among fresh juice industries

These machines work well for many of the applications above, but are generally more substantial, more expensive machines than many of those needs would necessitate. Screw-fed disintegrators are most applicable to hard-to-feed products like leafy greens.

They’re also ideal for metering the feed rate or moving the product into a grinding chamber at a consistent speed. Ginger is an excellent example of a product that works well in screw-fed disintegrators. The primary function of these machines is to overcome bridging as an issue for feeding the machine.

Pump Fed Disintegrators

In order for a pump-fed disintegrator to work properly for an application, the product in question must be pumpable.

Hummus is an excellent example of a product that responds well to pump-fed disintegrators. Cooked chickpeas pump smoothly through the feed line. The ground-up product is then moved on to a blending or mixing application without aeration or human contact.

Crushers

Food crushers are popular mostly in the food production industry. These durable and robust size reduction machines work in conjunction with disintegrators. They take large items like melons and break them up, so they are small enough to fit into disintegrators. In addition, food crushers can be used to break apart frozen food materials

Shredders

Shredders are used for grating vegetables and other food products rapidly at scale. Some are capable of taking large blocks or wheels of cheese and rapidly reducing them to a size that is easy to melt, and ideal for uses in pizza parlors and similar settings. Typical attributes include:

When it comes to these machines, it is important to remember that there is a difference between attractive, shredded cheese destined to be packaged for consumers, and shredded cheese that is easy to melt. While the typical shredder can produce bagged cheese, it’s better for creating a cheese that melts quickly in a commercial environment where attractiveness is less important.

In addition to the above, below are things to further consider prior to deciding on a machine that is best for you.

Budget

Before you begin shopping for your new piece of size reduction equipment, be sure you understand your budget and its restrictions. This will allow you to shop within your means and understand what you can get for your money.

Space Restrictions

Although most people assume size reduction equipment are huge, most angle disintegrators, for example, would fit in a 4x4x4 space. Some machines are larger but mobile and are designed to move from one room to another in a commercial production facility. As always, the footprint depends on process, output, yield, and horsepower.

Testing

Sometimes, end users are not sure if machine will work for their need and usually Want to see a machine in action before purchase it? Our manufacturer will help you test their machines with your products. Items can be sent to the lab for testing for combability prior to purchase. For inquiries outside of the USA, AfricanUSA Trade Connect will facilitate gathering of the items here in the USA and sent to our manufacturer’s lab. Contact us directly to learn more about this option.

How to Choose Screen Sizes and Accessories

While size reduction equipment is very straightforward, there are some available screens and accessories you can choose from. Here are a few considerations about each:

Power

The size and power of the machine is likely the most crucial consideration in this process. Size and power both affect output and volume, which, in turn, impact your bottom line. If you’re not sure what size machine you need, contact us to talk about your desired output and with the impute of our manufacturer and engineers help you design the most efficient, high-yield solution. If required, we can also create custom inlets and discharge chutes according to your specifications.

Size Reduction Equipment FAQs

Finally, below are a few of the typical FAQs to guide your purchasing process.

Q: How many passes does it take to grind a product to particle size desired?

Achieving the perfect consistency doesn’t necessarily happen in a single pass. In many cases, you’ll likely need various machines or at least various screens.

Q: Do I have enough room for these machines?

While most people assume size reduction equipment is very large, most units are small enough to fit easily into a commercial space. Angle disintegrators, for example, generally fit in a 4x4x4 space. Other units are larger, but all are designed to move from one room to another in a commercial production facility.

Q: How long is the lead time for a machine?

About 6 weeks without controls. A machine in stock or order placed during a slow time of year will speed that up. Adding controls takes it to at least ten weeks, but they are built concurrently with the machine to minimize development time. For most machines going to Nigeria and other Sub-Saharan African countries, contact us for lead time.

Q: What’s the typical lifespan of size reduction equipment?

Our manufacturer’s food size reduction equipment is built to last. The materials that make these machines are reliable and designed for longevity. Some of our manufacturer’s first machines are still out there running – many are 35+ years old and counting, although a 20-year lifespan is a safe bet for most machines and applications. Maintenance is key, however our manufacturer’s machines will last decades with proper care

Contact us today at www.afutrade.com or 847-504-7172 to discuss your unique need.